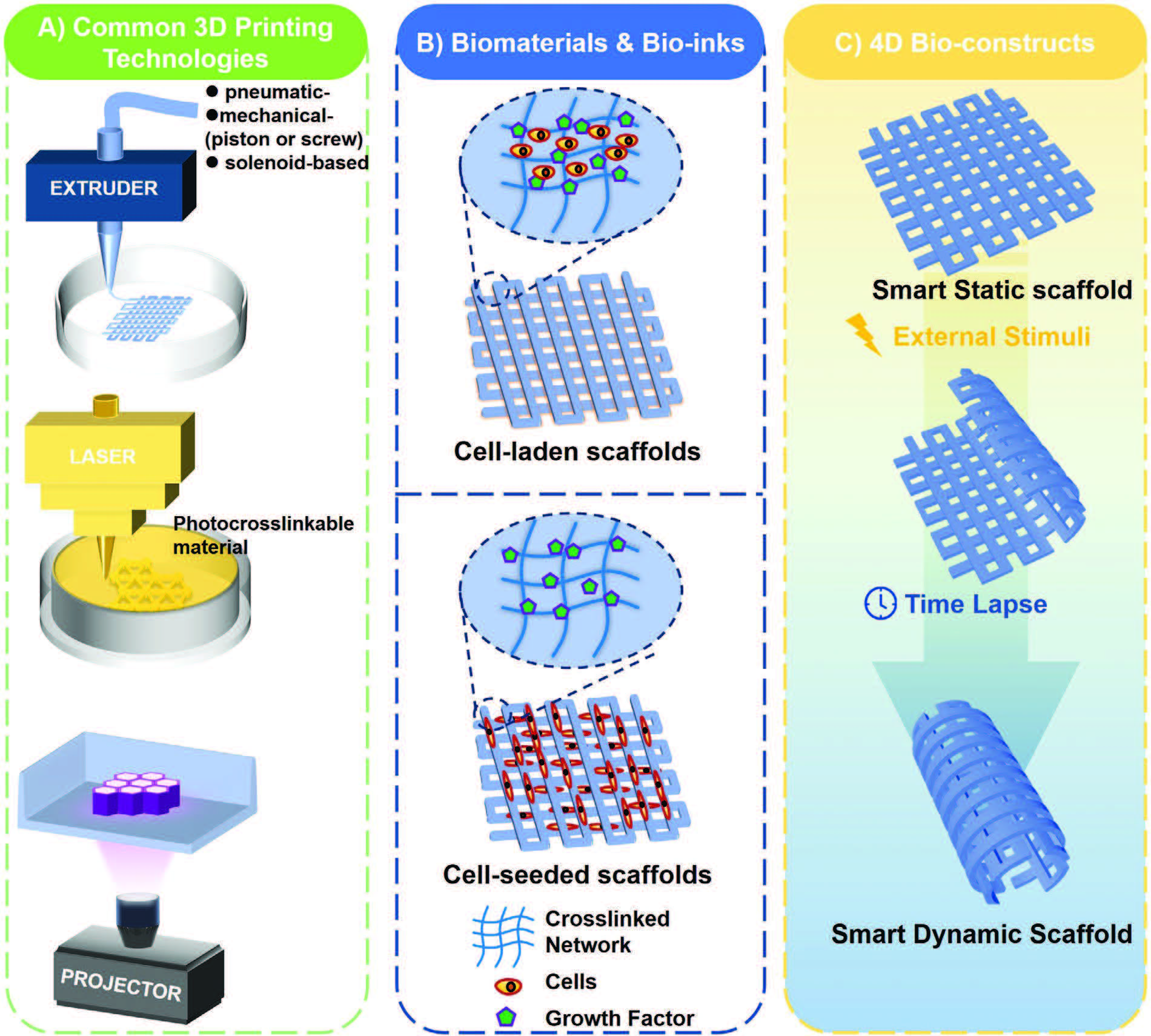

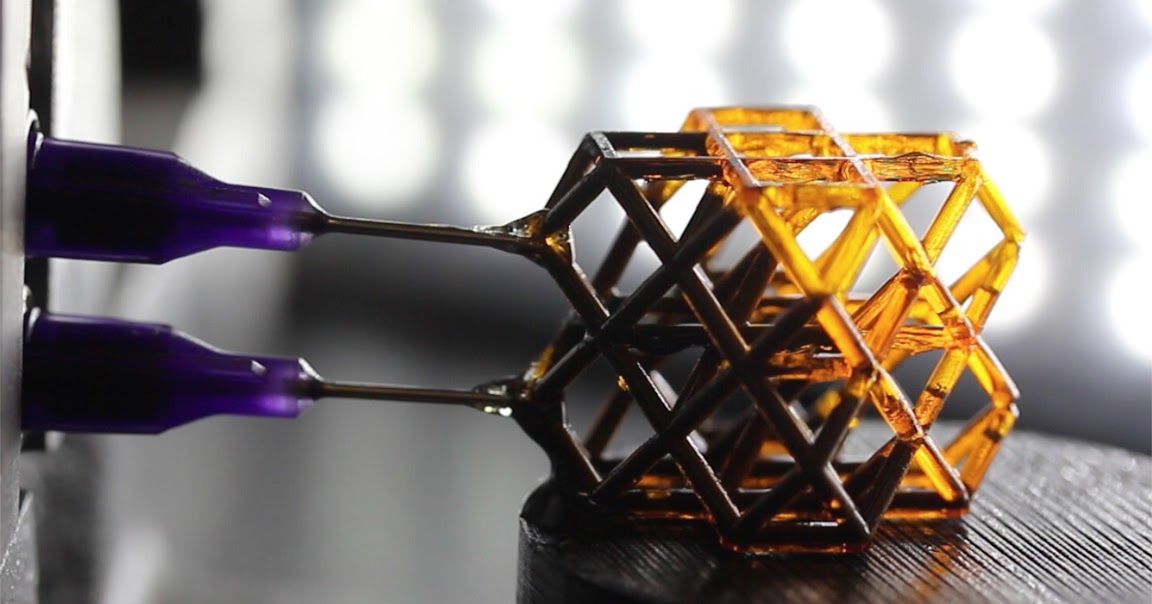

The 3 D Printer technology has revolutionized the manufacturing industry by his advent. To reduce the time taken by earlier technology, intelligent physical material can be programmed to build themselves. The brute force assembly technology takes a more time. INTRODUCTION : In this era of technology human are more dependent on machine in the field of manufacturing which is making their production of goods easier. In addition, the practical applications are depicted and the potential prospect of this technology is put forward. However, this short review illustrates the basic of 4D printing, summarizes the stimuli responsive materials properties, which have prominent role in the field of 4D technology. Contrast to all these developments, novel material is still a challenging sector. Improvements in Computer-aided design, additive manufacturing process, and material science engineering have ultimately favored the growth of 4-D printing innovation and revealed an effective method to gather complex 3-D structures.

This technology performs ingenious design, using smart materials to create advanced forms of the 3-D printed specimen. Adding time, as the fourth dimension, this technology ushered the potential of a massive evolution in fields of biomedical technologies, space applications, deployable structures, manufacturing industries, and so forth. The advancement in 3D printing has led to the rapid growth of 4D printing technology. We determined our review by aiming our future directions such as the "dream it and make it feasible" technology. Finally, we explored the future application potential under succeeding context: SMA-based knitted garments, transforming food, and relevant sectors wise development and proceedings with the advancement in smart materials.

Furthermore, the capabilities of single and multiple materials mechanisms for shape-shifting behavior are summarized. Starting from a generalized idea, and fundamental workflow, together with a graphical manifestation of the 4D printing concept, and 4D printing for shape-memory materials (SMMs), self-fitting wearables based on shape memory alloys (SMAs) are reviewed exclusively. Herein, the proposed review article discusses material arrangements for 4D printing, highlighting the structural evolvement mechanism, the behavior of deformation, and their prospective implementation with respect.

Although significant progress on smart material performance has been made and different studies have focused on new strategies and process improvements in typical additive manufacturing. Finally we summarize the current and future applications of 4D printing.ĤD printing is inspired by embedded product designs to produce stimuli-responsive consumables fabricated by available commercial 3D printers. The basic principle of 4D printing with multi material structure is to create precisely controlled localized internal stress with in a printed construct, which upon subsequent stress release can undergo further 3D shape shifting in a predictable manner In this review, we look into the main factors composing 4D printing technology such as smart materials and design. recently, rapid advances in printing process and materials development for 3D printing have allowed the printing of smart materials or multi-materials designed to change function or shape. In this context ,although similar to 3D Printing technology,4D printing technology adds the fourth dimension of time.4D printing allows a printed structure to change its form or function in time and response to stimuli such as pressure, temperature, wind, water and light. With a great potential to change everything from our daily lives to the global economy, significant advances in 3D printing technology have been made with respect to materials, printers and processes. D Printing has been recognized as a disruptive technology for future advanced manufacturing system.

0 kommentar(er)

0 kommentar(er)